1235-A, Jalan Paya Terubong,

11060 Air Itam,

Penang, Malaysia.

+604-828 3201

+604-829 7184

Display Range (48) View More | |||

Display Chiller |  Display Freezer |  YEM-1605 |  SMC-1502 |

Upright Range (16) View More | |||

Mo'Delux 2 door |  Mo'Delux 4 door |  Mo'Delux 6 door |  MDRT1471 , MDFT1471E |

Counter Range (40) View More | |||

2/3 Deck Drawer Counter Chiller |  Modelux Counter 750mm |  Modelux Counter 900mm |  Modelux Counter 1200mm |

SNH-0105 |  SNG-0105 |  SNC-0145 |  SNH-0155 |

Cake Chillers (13) View More | |||

RCS 12SB13-3FB |  RCS 12SS-2 |  RCS 12SS-3 |  SKS-1507Z |

Gelato Showcase | |||

CMC-3750O |  CMC-2500O |  CMC-1875O |  CMC-3750G |

SNL-2503 |  SNL-2103 |  SNE-1853 |  Krea 220.0 , 260.9 |

Walk in Cold Room |  Walk in Cold Room |  Walk in Cold Room |  Walk in Cold Room |

| |||

Japanese Style Open Showcase |  SMS-1810 |  SMS-1210 |  SMS-0910 |

SPC3-1807-AS |  SPC3-1507-AS | ||

Rent Walk in cold room | |||

SSC3-1807-AR |  SSC3-1507-AR | ||

Semi Contact Freezer |  Semi Contact Freezer |  Semi Contact Freezer | |

Vacuum Cooler Product features and main components Vacuum cooler is not a cold storage equipment, but cooling processing equipment, it is mainly based on the physical attribute that the boiling point of water reduces as the pressure drops. During the process, pre-cooling materials are vacuumized in vacuum tank, and the surface moisture will start to boil and evaporate when pressure reaches a certain numerical value, meanwhile, taking away plenty of heat. Through these steps, so that the material to achieve rapid cooling effect. Main feature:

Vacuum System Vacuum Pump Pre-cooling System :

Application : Mainly used foe vegetables, fruits, cut-flower, fresh meat and aquatic product, etc. 真空预冷机 产品物点及主要构件 真空预冷机不是冷藏设备,而是冷却加工设备。主要依据水的沸点随着压力下降而降低的物理属性,将预冷的物料置于真空槽子中抽真空,当压力达到一定数值时,物料表面的水分开始沸腾蒸发,并带走大量的热。从而使物料达到快速降温的效果。 主要特点:

主要构件: 真空系统 真空泵

压缩机 高质量耐磨轴组件和便于维护维护、使用与调速控制,运行平稳等特点,还配备有高效吸气冷却又的电机,既提高了压缩机使用寿命,且运行效率高 水冷冷凝器 气密性号,换热效率高,体积小,重量轻 冷却塔 散热胶片采用曲斜纹,有效延长循环水与冷却风在塔内气流更为合理,空气阻力减到最低,同事扇采用张形大风叶及长空间,在风机运转时更加平稳,从而降低了噪音大大提高冷却效果。 引用领域: 主要用于生鲜蔬菜、水果、鲜切花、鲜网及水产品等。 | |||

Vacuum Cooler |  Vacuum Cooler |  Vacuum Cooler | |

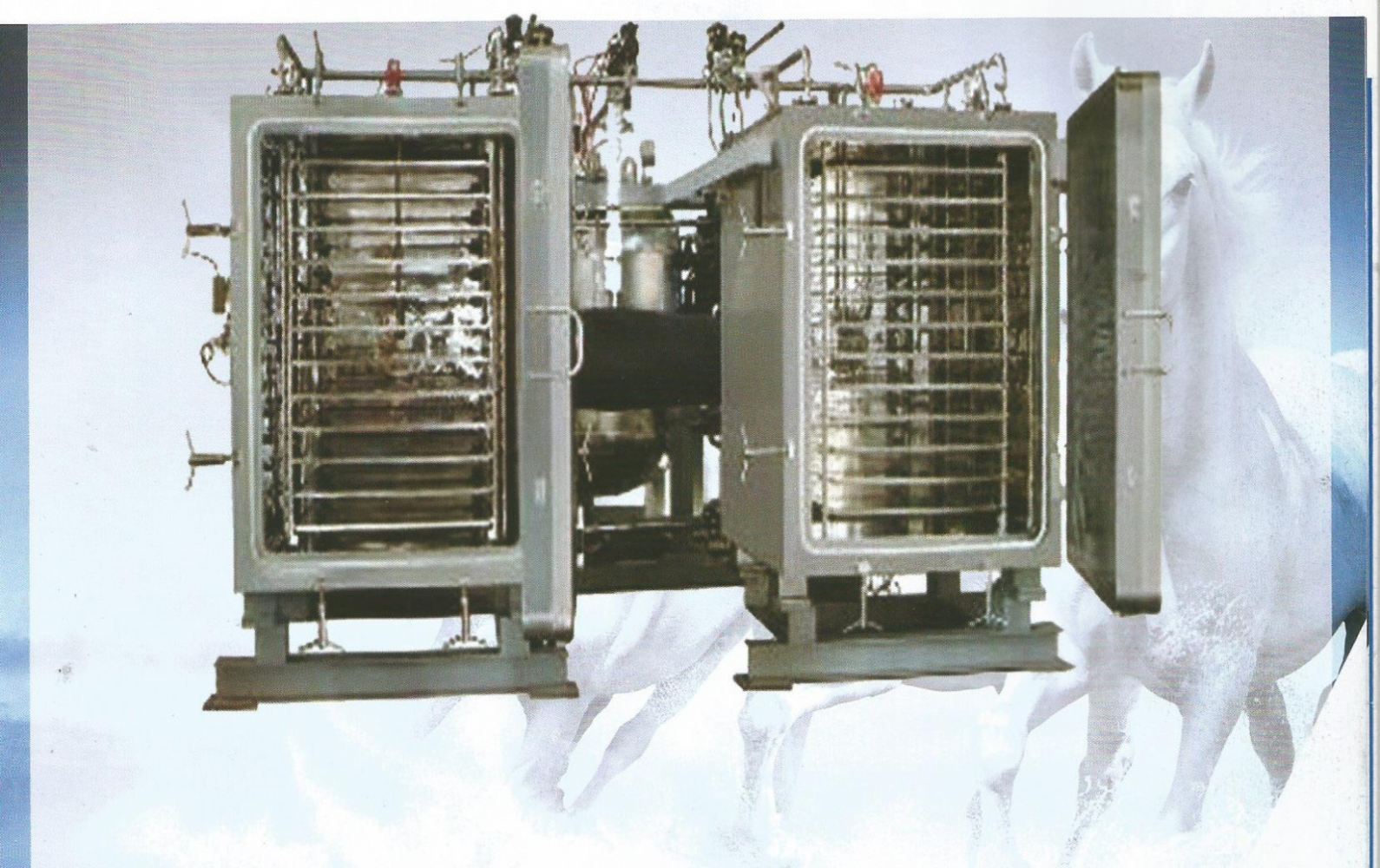

Vacuum freeze drier Features : Vacuum freeze drier, removing moisture in the food in vacuum situation to dry it. In the state of high vacuum, freeze driver lets the water of pre-freezing material turned into water vapor and removed directly under ice state without melting. During this process, vacuum drier can keep the nutrients in the food, especially for the volatile heat sensitive ingredients. Main Components: Drying oven, vapor condenser, cooling system, vacuum system, heating system, control system Drying Oven: A closed container integrated vacuum with drying function. Vapor Condenser : a sealing device for water vapor condensation and sublimation, usually located in the rear of drying oven and a large oven can be adsorption surface area inside. The vapor distilling from drying oven can be adsorbed in the metal surface, whose temperature will down to -45°C~ -65°C.While the condenser is a cylinder made of stainless steel or iron with inner condensing tube, which connects with the refrigerating units respectively and forms refrigeration cycle system. Heating System : The function of freeze drier heating system is to heat the material in drying oven, reaching constant sublimation so as to achieve the specified requirement for moisture content. Vacuum System: It is composed by multi-stage vacuum pump or water ring pump and Roots vacuum pump. For the roots pump is booster pump that can not be used alone, the vacuum pump or water ring pump must be firstly enabled. Cooling System: Freeze drier cooling system is composed by refrigeration compressors. Application: Chinese herbal medicine, creature, wild vegetable, dehydrated vegetable, food, fruit, chemical engineering, pharmaceutical intermediate, etc. 真空冷冻干燥机 产品特点: 真空冷冻干燥机,在真空状态下除去食品中的水分而达到干燥的且的。主要是在高空的状态下,使预先冻结的物料中的水分,不经过冰的溶化,直接以冰态升华为水蒸气被除掉。从而使物料达到干燥状态。真空干燥机可以确保食物中的营养物质,物别是易挥发热敏感性成分不损失。 主要构件: 干燥箱,水汽凝结系统,制冷系统,真空系统,加热系统,干燥系统 干燥仓 集抽真空与加热干燥功能为一体的密闭容器 水汽凝结器 是凝结结升水气的密闭装置,通常位于干燥仓后部,内部有一个较大面积的金属吸附面,从干燥仓物料中升华出来的水蒸气可凝结吸附在其表面上,吸附面的工作温度可达到-45°C 〜 -65°C,冷凝器外形是不锈钢或铁制成的圆筒,内部盘有冷凝管,分别与制冷机组相连,组成制冷循环系统。 加热系统 冻十机加热系统的作用是对干燥仓内物料进行加热,使物料不断的受热升华,从而达到规定的含水率要求。 真空系统 真空系统是由多级真空泵及罗茨真空泵组成,罗茨泵为增压泵不能单独使用,必须先启用真空泵或水环泵。 制冷系统 冻干机制冷系统由制冷压缩机组 引用领域: 中药饮片,生物,野生蔬菜,脱水蔬菜,食品,水果,化工,药物中间体等。 | |||

Vacuum Freeze Drier | |||

SVN-0455 |  SVN-0385 |  SVN-0255 | |